Air Compressor Not Starting

Lack or Insufficient Power

1. Check that the main voltage (power supply or outlet) corresponds to the

air compressor specifications.

Motor-Pump Overheating / Motor Failure

The thermal protector (internal motor-pump fuse) temporarily opened because the motor is overheating. With the exception of the CR series air compressors do not run motor continuously (non-stop) for more than 1 hour.

Mutiple times of overheating will permenately burn and danage the motor windings. If this occurs then the motor-pump will need to be replaced.

NOTE: With the exception of the CR compressor series, the majority of California Air Tools air compressors have a 70/30 Duty Cycle Rating - Learn More

Electrical Connectivity Issue

Vibration from compressor use/transport may have loosened a securing screw and might be interferring with electrical connectivity to pressure switch.

Remove power from air compressor by unplugging the power cable from power source. Remove the pressure switch cover (box) by removing 1 screw. Loosen and then retighten all screws which secure wired electrical connections. Reinstall cover and reapply power.

Air Lock (check valve spring compressed)

When pressure is left in an air tank for prolong periods of time, the check valve spring can become compressed cause the motor to not start.

2010A Check Valve Adjustment (generally applies to most models):

1P1060S/SP Check Valve Adjustment (generally applies to most models):

Tank is Full of Water

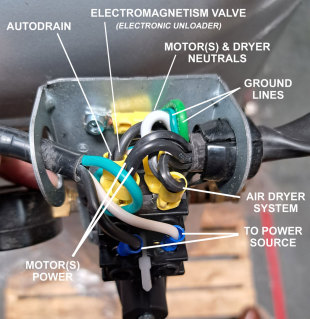

Pressure Switch Failure

Pressure switch worn or damage.

Pressure switch not turning on.

i.e. Reference 60040DCAD Pressure Switch Wiring shown below