Tips to Avoid Problems - DOs & DON'Ts

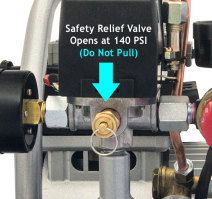

1. Do NOT pull on Safety Relief Valve! (i.e. this valve has the ring attached) as this will permanently damage the safety relief/pressure valve if used too often to bleed air out of tank. Upon initial unit purchase, it's ok to test one (1) time to verify relief operation. Majority of California Air Compressor Safety Relief valves will automatically open at ~140 PSI. Pressure Pot relief valves open at ~80 PSI. Only use the manual ball drain valve or your air tool to remove air from the tank. 'AD' Units equipped with an Automatic Drain Valve will evacuate water and a small percentage of air on a regular basis.

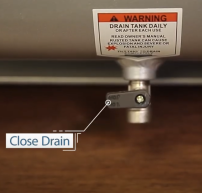

2. Remove water from the tank on a regular basis! Not doing so can cause inadequate pressure problems. Open Manual Ball Drain valve at base of unit to let water condensation buildup out. Automatic Drain Valve (AD) equipped units will remove water from the tank on a regular basis.

NOTE: 80% & 98% Dry Air Models (i.e. DCAD/DCADC) feature a Manual Ball Drain & Strainer w/Built-in Automatic Drain Valve. To manually drain the tank, turn the Strain Relief cap Counterclockwise and turn the black lever 90 degrees to release water, then close. Thoroughly clean strainer/mesh (located inside) of particulates; reattach Strain Relief cap and tighten Clockwise.

3. Do NOT Hot Plug the unit! (i.e. pull power cord from wall receptacle and then plug into another receptacle). This will usually cause the motor to start HUMMING LOUDLY and may permanently damage the motor-pump assembly.

4. Ensure Filter(s) and Filter Tube(s) is attached to motor! This will ensure the unit runs as quiet as possible. 1 Hp motors use one filter, 2 Hp motors use 2 filters.

5. Do NOT pull on power cord or air hose to move your unit around! This can damage the electrical connections and/or allow air to leak from air hose/coupler fittings.

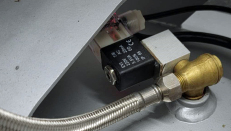

6. Avoid connecting air compressor to Remote Power Switches! Only California Air Tool models equipped with an electronic unloader valve (pictured below) are safer for these types of applications otherwise permanent motor-pump damage may occur. All California Air Tool products are designed for attended operations only (i.e. during working hours and with personnel present). See #9 below.

7. It is suggested to add Teflon tape to Air Hose threads! (i.e. remove Industrial Male 1/4 NPT and Industrial Female 1/4 NPT couplers from your air hose and add Teflon tape to 3/8" threads - this will help prevent air leaks and reduce compressor motor-pump(s) running time.

8. Do NOT operate any California Air Tool unit in Severe Elements! This includes outdoors in the rain (high levels of precipitation), below freezing (<32F), excessive heat environments (i.e. >90F) and high-dust & particle environments (i.e. ingestion into motor-pump). Generally units should operate below 85F (when used for long periods of time) otherwise motor-pump overheating could occur and the internal motor-pump's thermal fuse may suddenly shutoff the unit off for ~10-15 minutes.

9. Do NOT exceed compressors rated Duty Cycle! Most air tools and machines are rated for intermediate usage (not continuous).

Always consult the air tool or machine manufacturer for the correct air flow volume/ CFM (cubic feet per minute) requirement.

Baseline Rule: With respect to air compressor use/operations, 70/30 Duty Cycle rated motor-pumps should not be allowed to continuously operate for more than ~60 minutes (i.e. where you hear the motor-pump running the whole time), otherwise permanent motor windings damage may/will eventually occur in time. After ~50-60 minutes of continuous running (60 mins maximum!), all air compressors with 70/30 Duty Cycle rating, should be allowed to cool down for 15-20 minutes, then compressor operations may repeat. Moreover, for 1 HP motor-pump air compressors it is suggested to avoid running continuously more than 30-45 minutes at a time. Usage assumptions are based on a standard 8 hour work day, 5 days/week.

Exception: all Continuous Run air compressors (i.e. 20020CR, 20020CR-22060, 10020UDCR, 60050SCR) are designed and may safely run continously for 8-12 hours, depending on PSI and CFM levels.

Continuous Operations: 2 Hp, 4 Hp, and 6 Hp models may operate continuously from 1 to 4 hours if the air flow volume cfm (@ desired PSI) is divided by 2 as this will allow the motor-pumps(s) to cycle ON/OFF on a regular basis allowing the motor windings to cool down regularly. Divide by 3 for 4-8 hour operations. Divide by 4 for longer than 8 hours/day though prolonged compressor operations is not suggested and may void product warranty should a compressor issue occur. Under any scenario, refer to Baseline Rule above as the motor-pump(s) should never be heard running continuously for more than 1 hour (except for CR series). For example, if the compressor cycles ON for 2.5 minutes and is then OFF for 5 minutes, and repeats this cycling, then this is usually considered permissible operation for up to a few hours at a time (i.e. Dental Milling/CO2 Laser Cutting, etc). NOTE: If tooling CFM flow is unknown then it is suggested to either measure with a cfm flow meter or adhere to the 60 minute maximum motor-pump(s) Running ON time.

Attended Operations Only: All California Air Tools products are designed for standard work day environments with attended operation only and are not designed for 24/7 and/or unattended operational environments. Unattended operations is not suggested for safety reasons as motor-windings may become excessively hot (and may fail) if compressor runs higher or longer than the product's rated duty cycle (i.e. due to unknown cfm rates or a sudden rapid air leak/loss in the application/tooling system).

Case Example: Dry Air System failure (pictured below) due to compressor running 24/7 and left unattended for several months without any maintenance (water tank was not drained & dry air system clogged; desiccant flowed out side of dryer system tower and down the wall):

10. Do NOT operate unit on it's side! Generally all California Air Tool units need to operate vertically, with no more than a 15 degree tilt with respect to gravity. All single-stage and two-stage motor-pumps have 2 pistons that move up and down rapidly inside the motor.

11. Avoid connecting unit to GFCI electrical outlet! Some GFCI receptacles (found in most newer or upgraded homes today) can interfere with air compressor unit function; switch to another electrical outlet if this occurs.

12. Do NOT use unit with extension cords greater than 25' in length! Ensure you have a proper cord gauge rating (i.e. 10/12/14) and unit is properly grounded.

13. Do NOT remove or replace Industrial Female fitting as this will void your warranty. The Air Compressors Female fitting (or fittings) is attached with high-grade locktite to the manifold and can only be removed using a Heat Gun. The manifold assembly may crack and leak air if improperly modified/serviced. CAUTION: for servicing personnel only!

14. California Air Tools is the only air compressor manufacturer that includes an Easy Start Valve on 2 Hp Air Compressors and above.

The Easy Start Valve blows air during startup (2, 4 & 6 Hp models). The valve will blow and release air from motor-pump for 2 to 15 seconds on average - this is NORMAL. The purpose is to reduce Amp (current) draw for easier air compressor start which helps prevent a breaker from tripping. TIP 1: Ensure Ball Drain Valve is closed or air will continue to blow out of easy start valve. TIP 2: On 220 volt models if voltage is too low (i.e. less than 210 volts) then start valve may continuously blow air. See Video below:

15. It is not suggested to run air through hard conduit lines. Running air from a typical polymer-based hose to hard conduit (copper, aluminum, steel) may cause high levels of condensation (water) to build up within lines due to minor thermal (temperature) changes during the air transfer from one point to another - particularly over longer distances (i.e. through walls, floors, etc). If excessive water build-up is observed then it is suggested to install a standard in-line dessicant air cleaner/dryer (example only) or commercial grade Refrigerated Dryer (15 cfm example only) or Refrigerated Dryer (10 cfm example only) at the final point of tooling/application to remove moisture/water buildup.

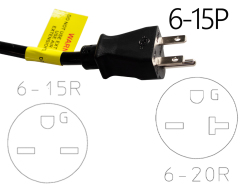

16. Connectivity Tip. If you purchased a 220 volt only California Air Tools model (2 Hp or 4 Hp) the unit comes with a 6' power cable with a NEMA 6-15P plug. The corresponding electrical wall plate/receptacle with need to be either a NEMA 6-15R or 6-20R. A dedicated 20 Amp breaker is also suggested.

17. For 80% & 98% Dry Air Models Replace Desiccant every 4000 Hours! (approximately 2-3 years with average daily use).

80% AIR DRYER UNITS: Replace 1 lb activated alumina/dessicant beads within a mesh bag located inside each vertical chrome tower (unscrew bottom to remove mesh bag, unzip the mesh bag, discard dessicant beads and replace with new dessicant). Purchase activated alumina via the Factory Outlet Store.

98% AIR DRYER UNITS: Replace the Ultra Dry Service Kit cannister and replace with a new one (turn counterclockwise to remove). Purchase via the Factory Outlet Store.

Questions?

Our Service Staff will happy to address any questions you have:

Customer Service Department Hours:

M - Th 8am - 3 pm Pacific Time

Friday 8am - 1 pm Pacific Time

E-mail: customerservice@californiaairtools.com

Phone: (866) 409-4581 Ext. 1